Magnetıc Chuck – Quıck Mold Change Systems

Overvıew

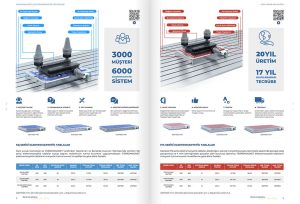

FERROMAGNET Quick Mold Change Systems replace traditional U-clamp and bolting methods, offering a faster, safer, and more effortless way to secure molds. By ensuring molds are fixed in the same position every time, they enhance product quality and production consistency.

They provide high efficiency in press machines and mass production lines. With a robust structure that keeps the mold securely in place even during power outages, they are durable and reliable. Mold size, holding force, and control systems can be customized to meet specific customer needs.

1

+

Magnetic Chuck Production

1

+

Satisfied Customer

1

+

Multiple Countries

1

+

Years of Experience

FREQUENTLY ASKED QUESTIONS

Quick Answers for Smart Decisions

Explore our most common questions to make confident choices about magnetic clamping systems, automation, and more.

What is the holding force of Ferromagnet electromagnetic chucks?

Ferromagnet chucks provide holding forces ranging from 16 to 17.5 kg/cm², depending on the series and application.

Are Ferromagnet systems compatible with all CNC machines?

Yes, our magnetic chucks can be integrated with various CNC milling, grinding, and machining centers.

Can thin or small parts be held securely?

Yes, models like the P15 Series are specifically designed for thin workpieces and ensure strong, even holding without deformation.

What is the power requirement for the electromagnetic systems?

Our systems typically operate with standard industrial voltage (e.g. 220V/380V) and include a dedicated control unit for safe use.